12.2.7.1. Interaction of Shear and Tension for Bolts

Traditional analysis methods only cover the interaction effects of shear on the shank of the fastener and tension alone on the threaded portion. The most recent and best reference for this interaction effect can be found in (![]() NASA-TM-2012-217454, 2012).

NASA-TM-2012-217454, 2012).

This analysis is valid for bolts installed in metal and composite components as it considers only the fastener in isolation.This reference examines fasteners loaded at the shank in combined shear and tension loads and also, in the threaded portion in combined shear and tension loads.

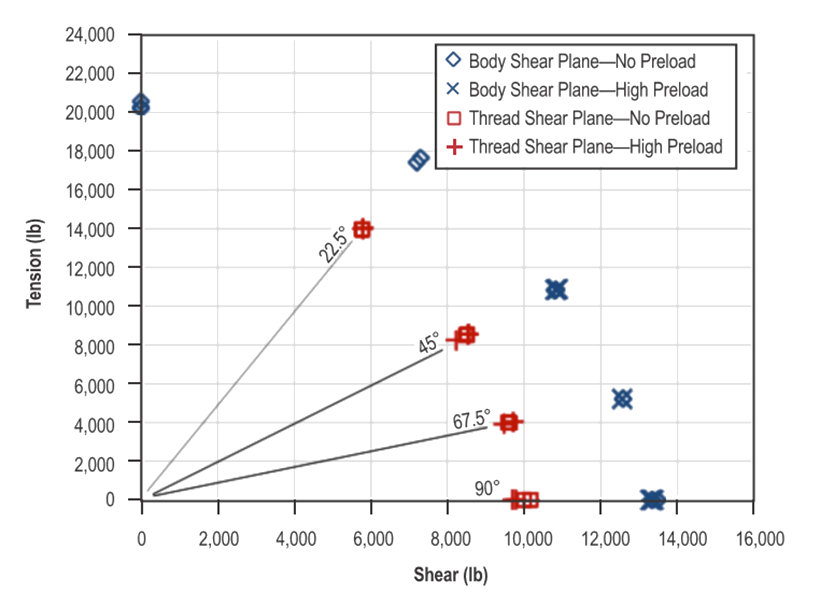

All of the testing represented in this reference was on 3/8in diameter bolts and lubricant was used to minimize the potential for load transfer by friction. The first round of testing done was to compare the ultimate combined strength of the bolt with and without preload.

NASA-TM-2012-217454, 2012)

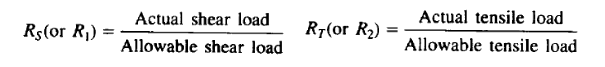

NASA-TM-2012-217454, 2012) When a fastener is subjected to both tensile and shear loading simultaneously, the combined load must be compared with the total strength of the fasteners. Load ratios and interaction curves are used to make this comparison, the load ratios are:

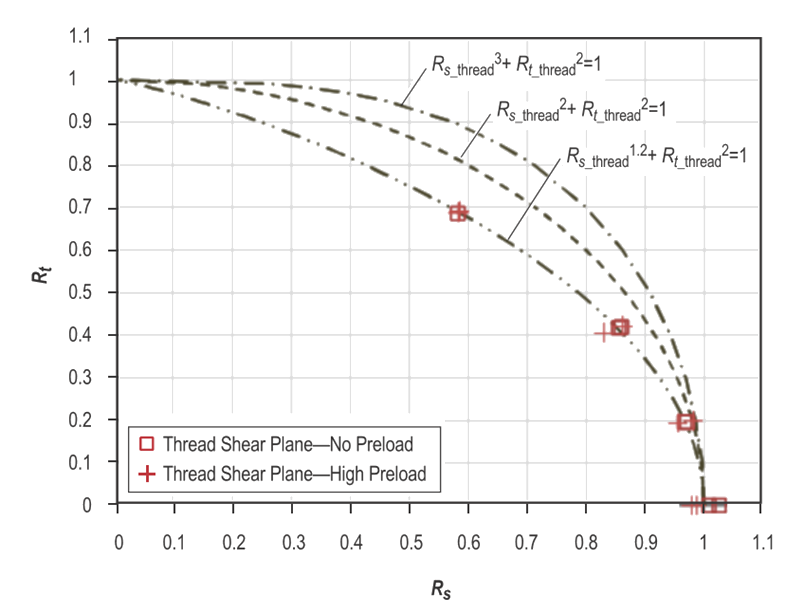

From Figure 12.2.7‑1 two clear conclusions can be drawn:

- The presence or lack thereof of preload does not affect the ultimate strength of the joint in tension or shear (although it is critical for the fatigue life of the joint).

- The strength of the joint is significantly affected if the fastener is loaded in the threaded area.

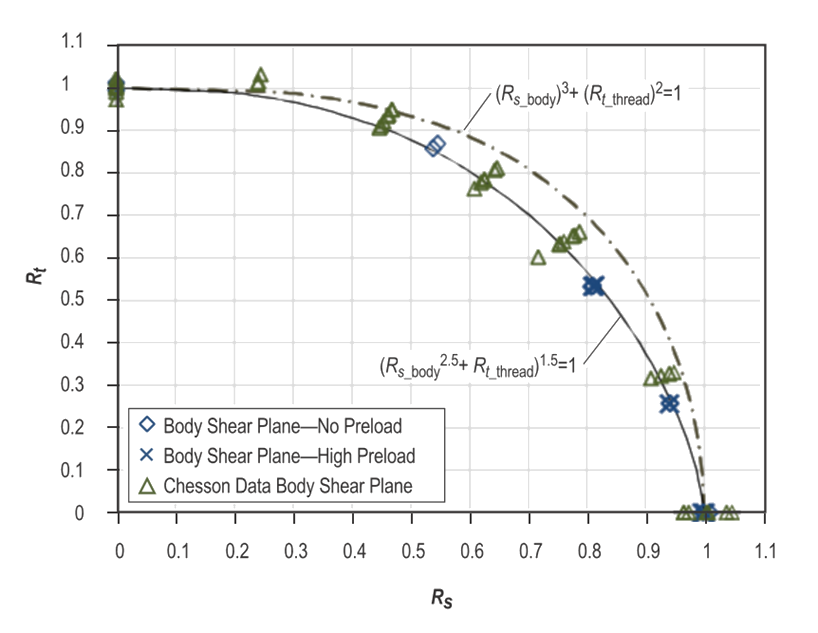

The reference (![]() NASA-TM-2012-217454, 2012) gives some further guidance on the definition of the interaction of shear and tension.

NASA-TM-2012-217454, 2012) gives some further guidance on the definition of the interaction of shear and tension.

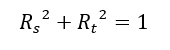

For fasteners loaded in the unthreaded shank:

NASA-TM-2012-217454, 2012)

NASA-TM-2012-217454, 2012) The interaction equation for fasteners loaded in the unthreaded shank (recommended for primary structure) is:

A spreadsheet for this interaction is available at the link below:

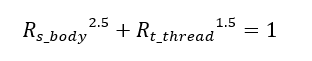

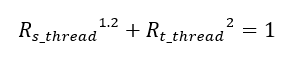

For fasteners loaded in the threaded portion:

NASA-TM-2012-217454, 2012)

NASA-TM-2012-217454, 2012) The interaction equation for fasteners loaded in the thread is:

A spreadsheet for this interaction is available at the link below:

12.2.7.2. Interaction of Shear and Tension for Rivets

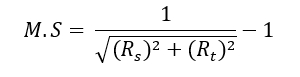

The established method for interacted load effects on rivets is:

Therefore, the margin of safety can be calculated directly using the following expression:

12.2.7.3. Fastener Bending

When very thick sheets are fastened together and non-working shims are used, the offset introduced can create a bending effect on the fasteners in the joint.

These effects rarely occur in a well-designed joint using a field of fasteners. In a fastener field, the bending moment caused by an offset between load paths is carried over the area of the joint and not by an individual fastener or fasteners.

For a joint that relies on a single highly loaded fastener or has very few fasteners, has unusual geometry, has a poor fastener fit (for example, a slotted hole), with low installation torque, in thick items; then bolt bending may be considered, but it is almost always conservative to do so. Bolt bending is more typically considered for lug analyses, see section 12.2.10.1.