Reference: Abbott, Richard. Analysis and Design of Composite and Metallic Flight Vehicle Structures 3 Edition, 2019.

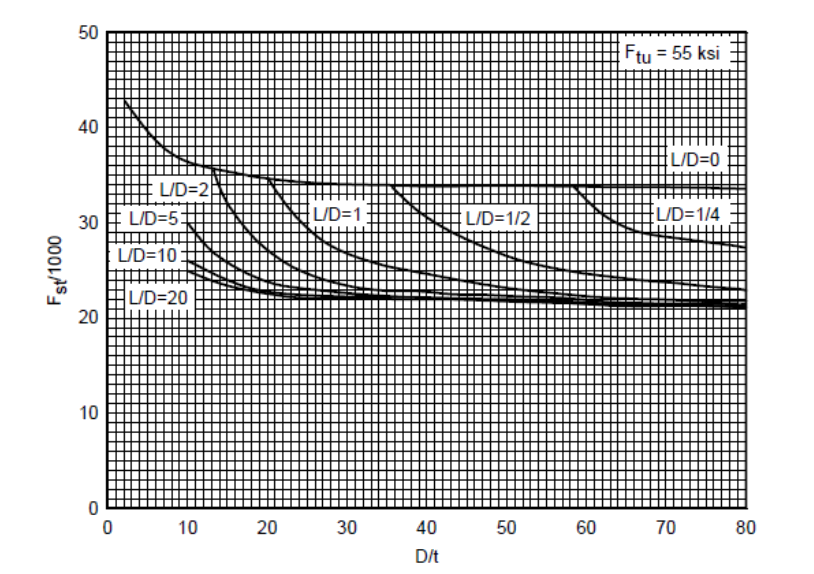

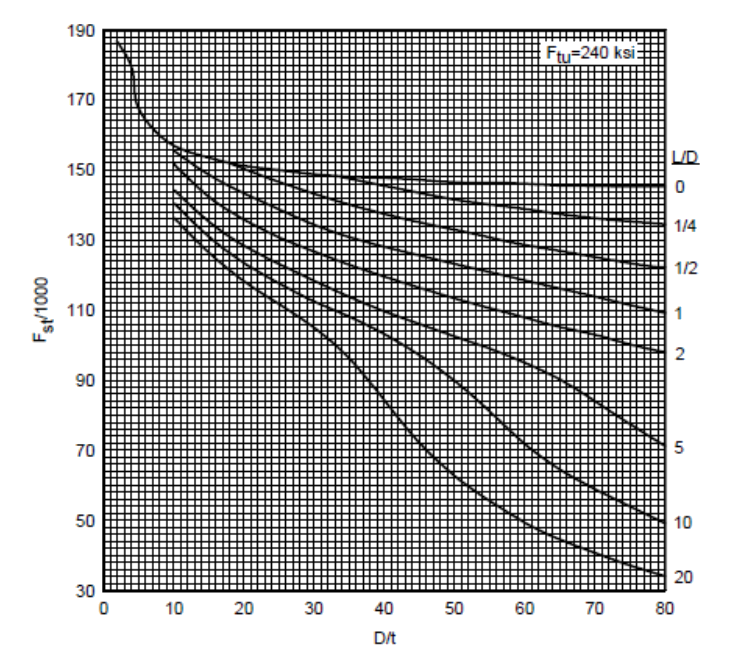

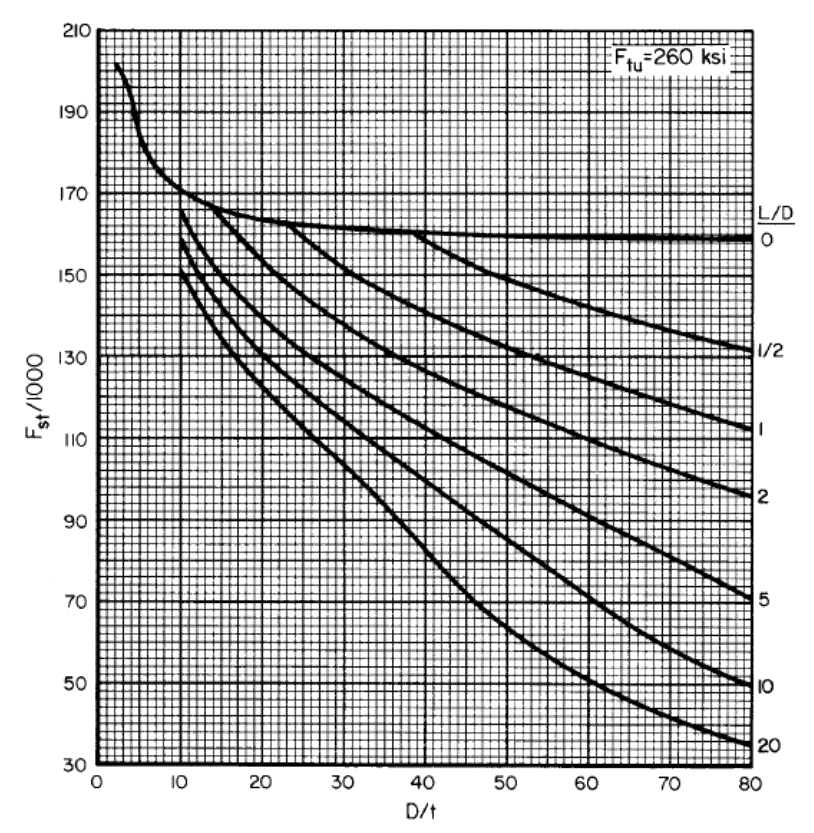

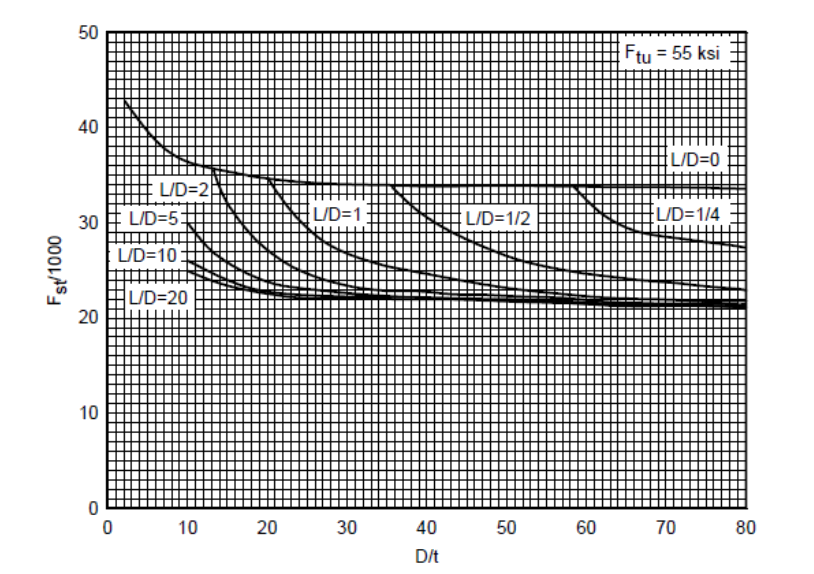

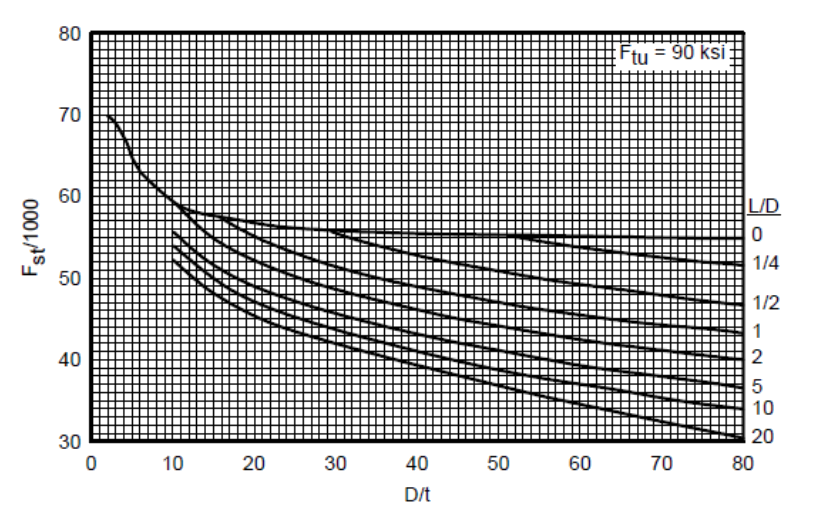

For circular cross sections the following figures give the torsion modulus of rupture for a range of steels:

Figure 9.1.1‑1: Torsional Modulus of Rupture – Plain Carbons Steels Ftu = 55ksi (

Figure 9.1.1‑1: Torsional Modulus of Rupture – Plain Carbons Steels Ftu = 55ksi ( MIL-HNDBK-5H, 1998)

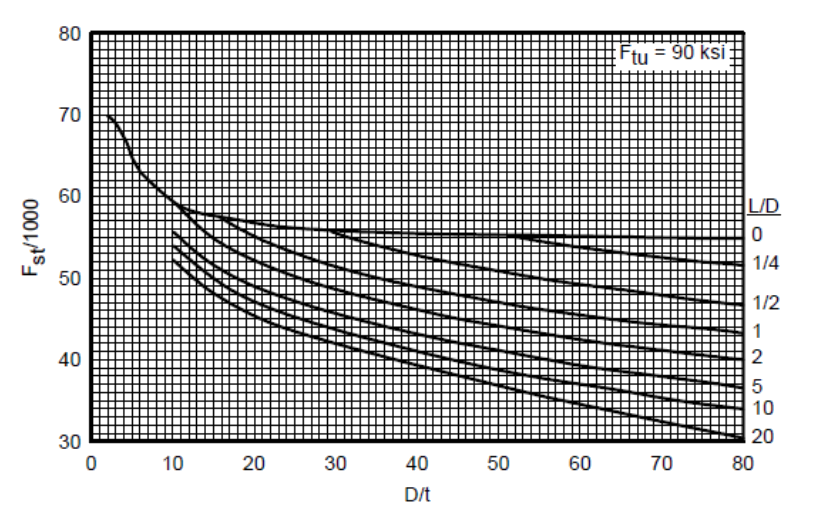

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑2: Torsional Modulus of Rupture – Low Alloy Steels Treated to Ftu = 90ksi (

Figure 9.1.1‑2: Torsional Modulus of Rupture – Low Alloy Steels Treated to Ftu = 90ksi ( MIL-HNDBK-5H, 1998)

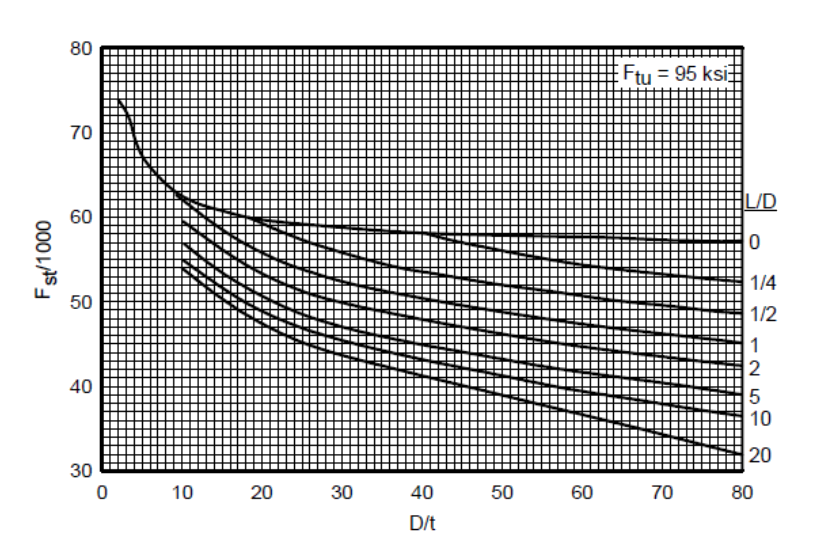

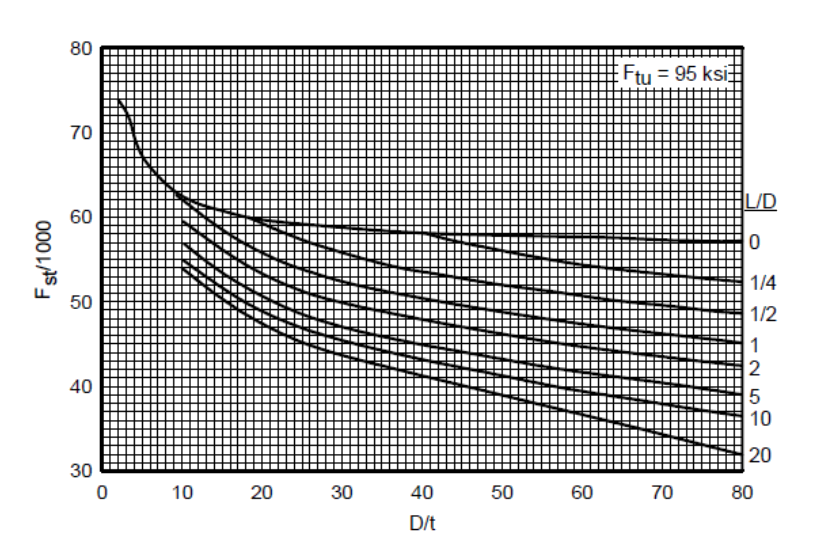

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑3: Torsional Modulus of Rupture – Low Alloy Steels Treated to Ftu = 95ksi (

Figure 9.1.1‑3: Torsional Modulus of Rupture – Low Alloy Steels Treated to Ftu = 95ksi ( MIL-HNDBK-5H, 1998)

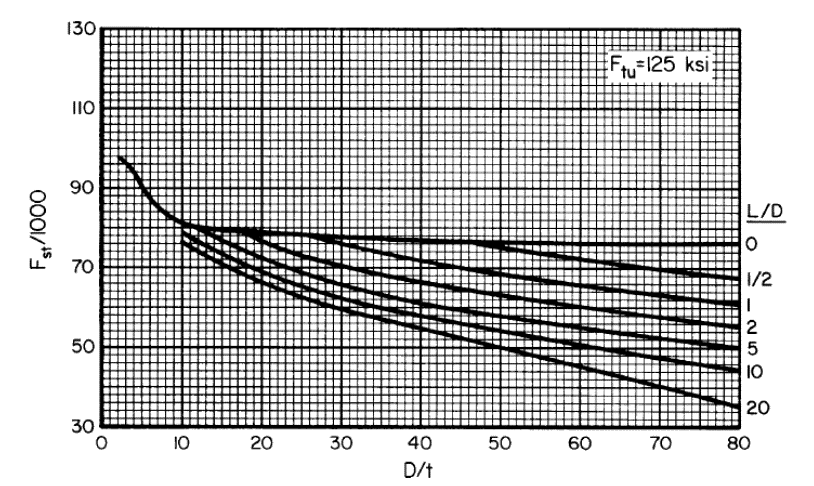

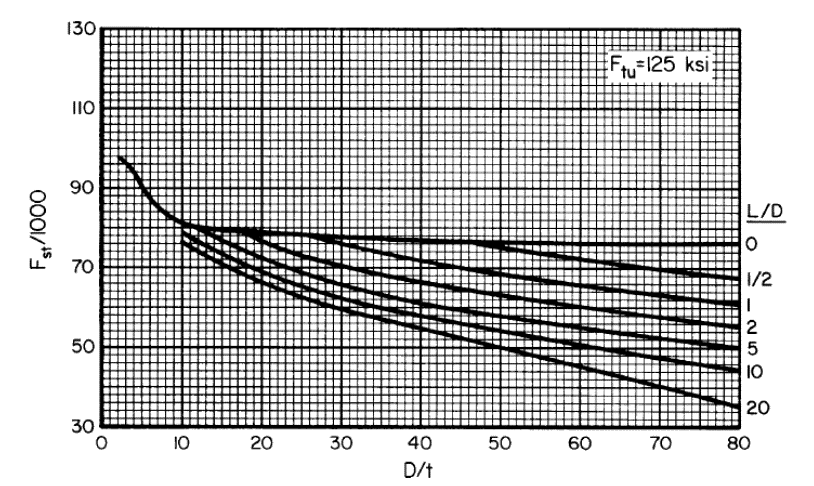

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑4: Torsional Modulus of Rupture – Low Alloy Steels Heat Treated to Ftu = 125ksi (

Figure 9.1.1‑4: Torsional Modulus of Rupture – Low Alloy Steels Heat Treated to Ftu = 125ksi ( MIL-HNDBK-5H, 1998)

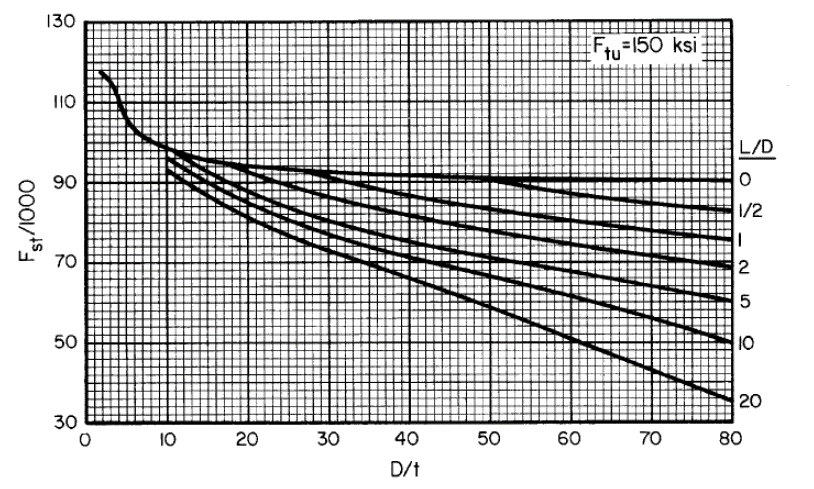

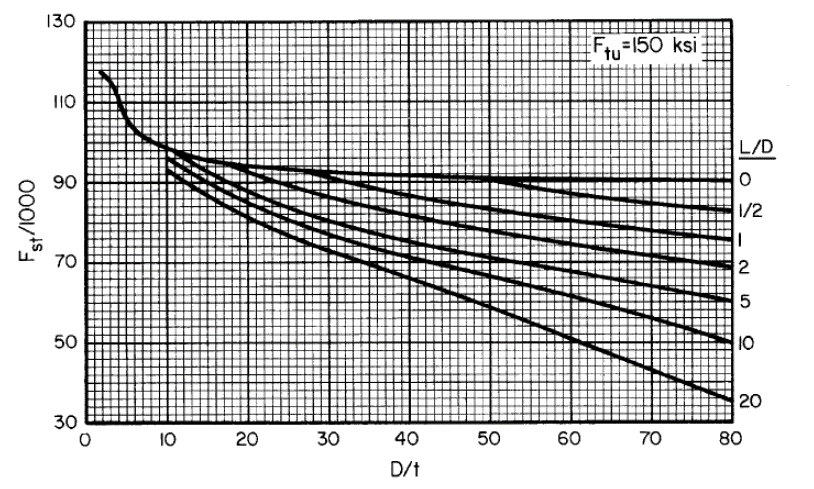

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑5: Torsional Modulus of Rupture – Low Alloy Steels Heat Treated to Ftu = 150ksi (

Figure 9.1.1‑5: Torsional Modulus of Rupture – Low Alloy Steels Heat Treated to Ftu = 150ksi ( MIL-HNDBK-5H, 1998)

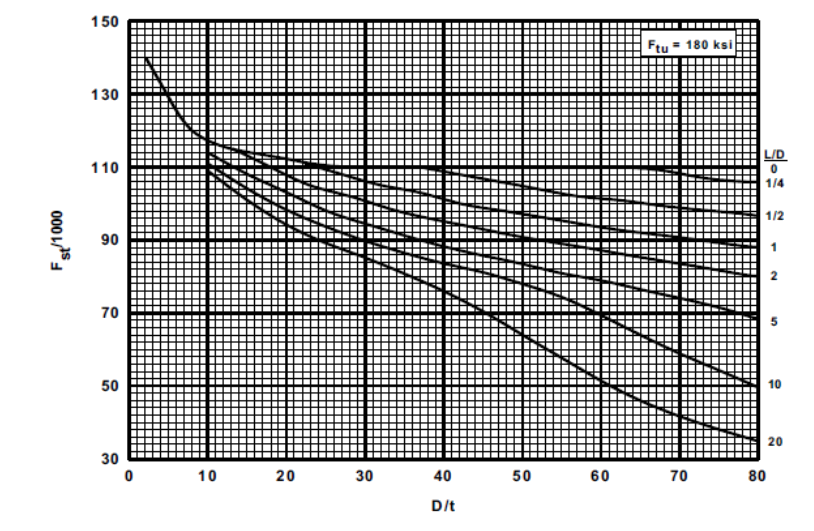

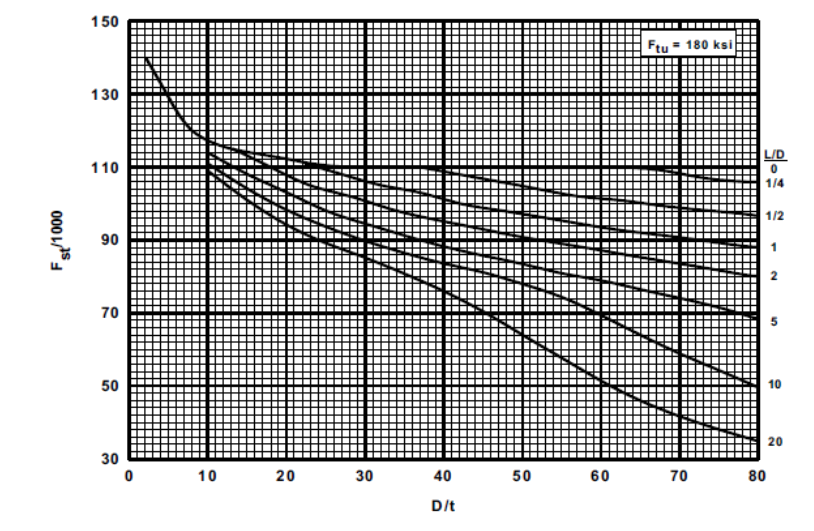

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑6: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 180ksi (

Figure 9.1.1‑6: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 180ksi ( MIL-HNDBK-5H, 1998)

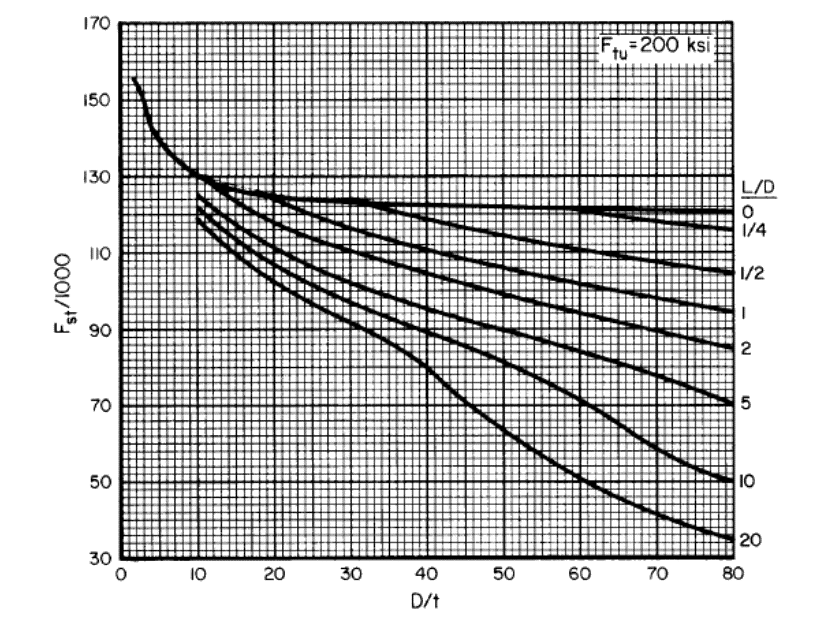

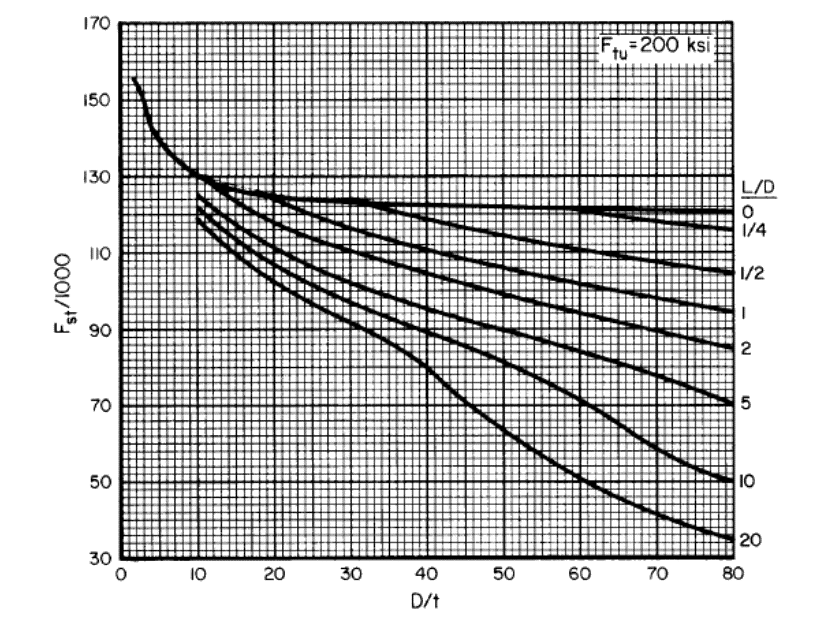

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑7: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 200ksi (

Figure 9.1.1‑7: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 200ksi ( MIL-HNDBK-5H, 1998)

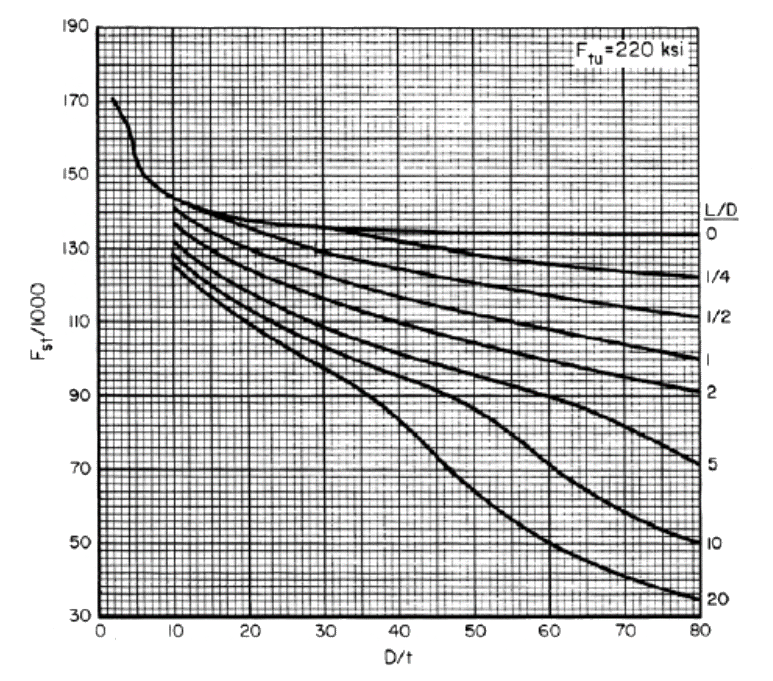

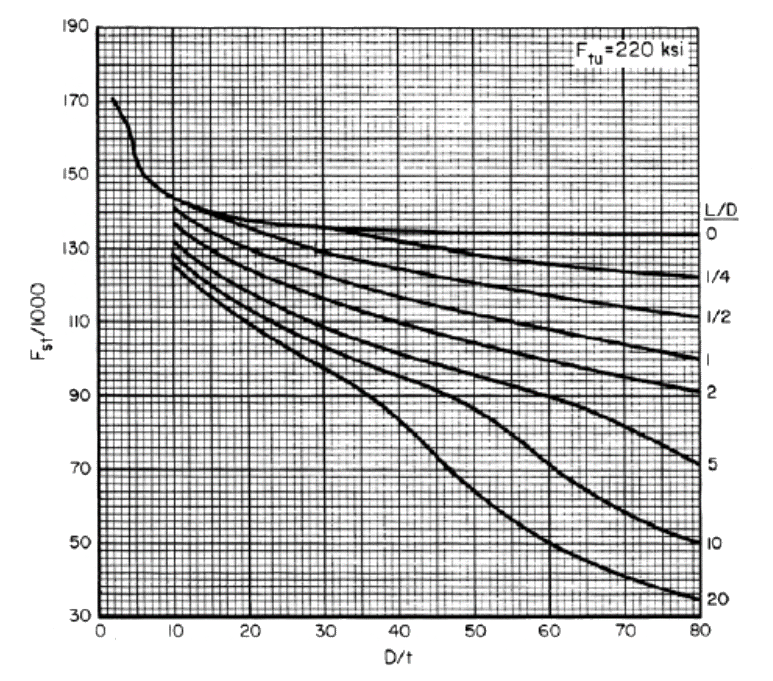

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑8: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 220ksi (

Figure 9.1.1‑8: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 220ksi ( MIL-HNDBK-5H, 1998)

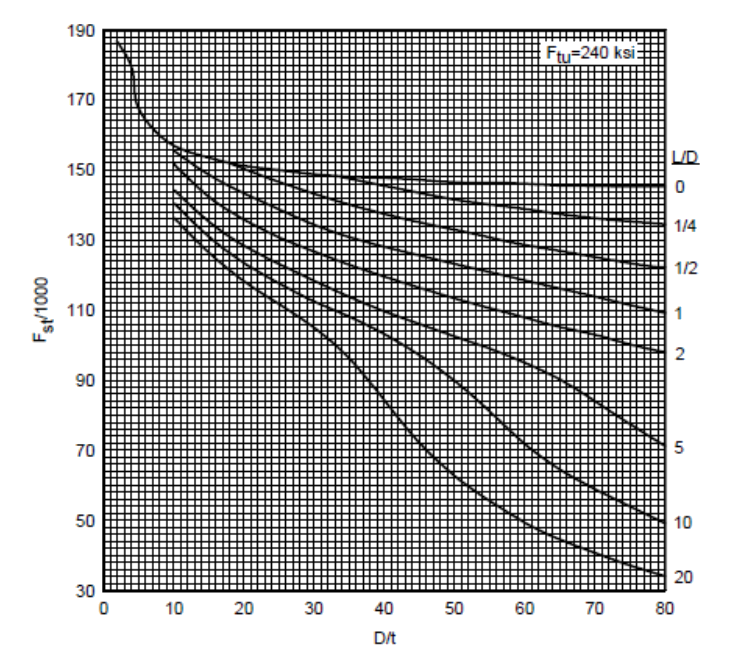

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑9: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 240ksi (

Figure 9.1.1‑9: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 240ksi ( MIL-HNDBK-5H, 1998)

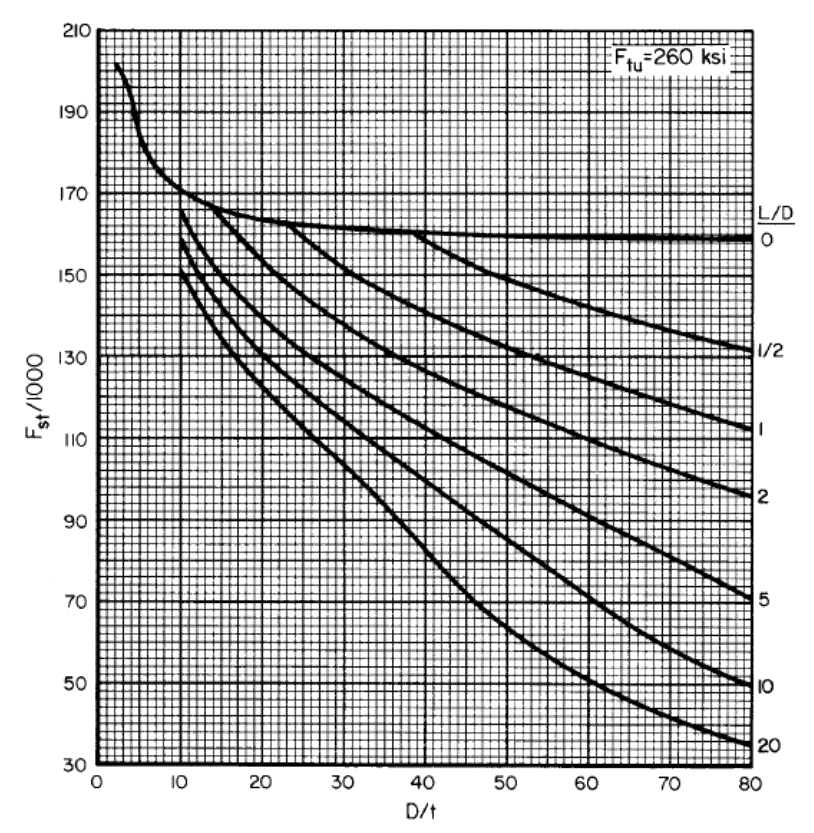

MIL-HNDBK-5H, 1998)  Figure 9.1.1‑10: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 260ksi (

Figure 9.1.1‑10: Torsional Modulus of Rupture – Alloy Steels Heat Treated to Ftu = 260ksi ( MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)

MIL-HNDBK-5H, 1998)