Writing the text book has been a good opportunity to go and re-examine the fundamentals of panel buckling analysis.

Shear Buckling of a thin (elastic) panel is a good place to start.

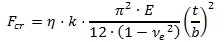

First of all, Terms:

Why use the term elastic buckling? When you use Young’s Modulus to calculate the buckling allowable no allowance is given for yielding of a ductile material such as aluminum. For relatively stable panels the theory above can give very high buckling allowables, greater than the ultimate strength of the material. This is not realistic and the result from this type of analysis may have to be modified for material non-linearity. We will cover that in a later post.

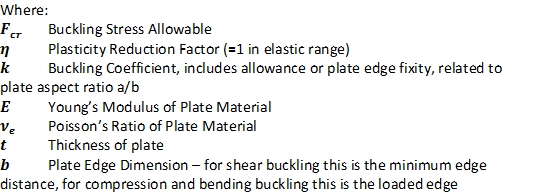

Where does k come from?

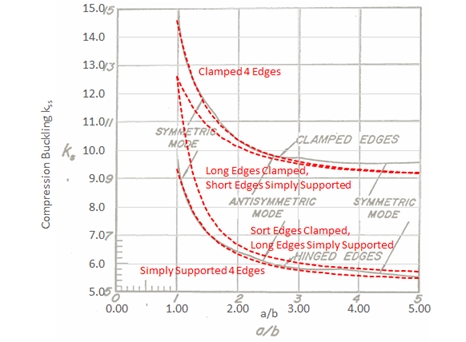

k is related to the panel aspect ratio in the following way. These curves are available in many references, we recommend (NACA-TN-3781, 1957)

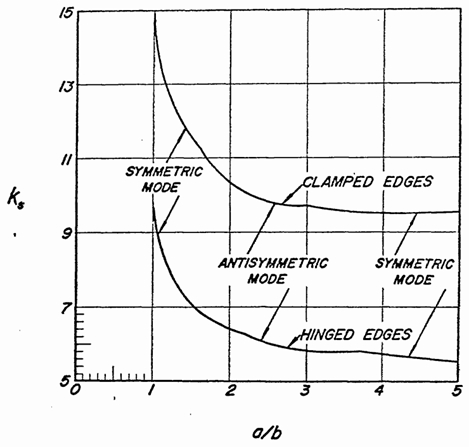

These curves can be accurately approximated by the following expressions:

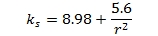

For a plate simply supported on four edges:

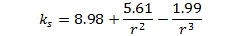

For a plate clamped on four edges:

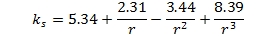

For a plate clamped on the long edges and simply supported on short edges:

For a plate clamped on the short edges and simply supported on long edges:

Where r = a/b.

Superimposing these curves over the classic reference for k:

How do you assess whether a panel is simply supported (hinged) or clamped for the purpose of analysis? For a first check it is recommended that the panel be considered simply supported. This will give a conservative first estimate of the panel buckling strength.

Our spreadsheet to calculate this first conservative check is linked below.

More to follow on more accurate assessments of panel edge fixity states in post 2, and dealing with calculated buckling allowables above the material elastic limit.

To try our free Stress Analysis Engineering Spreadsheets click below

To try our Add-in for Microsoft Excel for Windows click below

Comment On This Post